|

|

EPOXY COATED STEEL TANKS

efusion® is the brand name for Balmoral Tanks’ in-house steel panel epoxy coating. This fusion bonded epoxy treatment provides a highly resistant coating to the tank panels. The benefits of epoxy coated steel tanks against more traditional tank coatings include higher durability to impact, lower cost manufacturing, lower carbon footprint and more efficient design principles. Efusion is tested to similar stringent standards as glass coated steel and meets or exceeds the following internationally comparable coating requirements: ➠ISO 12944 ➠EEA 7.24 ➠WIS 4-25-01 ➠EEA 7.25 ➠ISO 28765:2008 ➠AWWA D103-09 ➠EEA 7.20 ➠WRAS

Tested to 1500V, the efusion 1500 coating delivers the highest level of durability and performance available in the storage tank market.  With value engineering at the heart of material selection, Balmoral Tanks’ efusion coating meets all necessary design life expectations. Key factors in achieving optimum product performance begin with the design and manufacturing process, running right through to installation. Retaining in-house control and quality in each of those critical areas is vital in ensuring consistent high levels of performance of any coated steel tank.

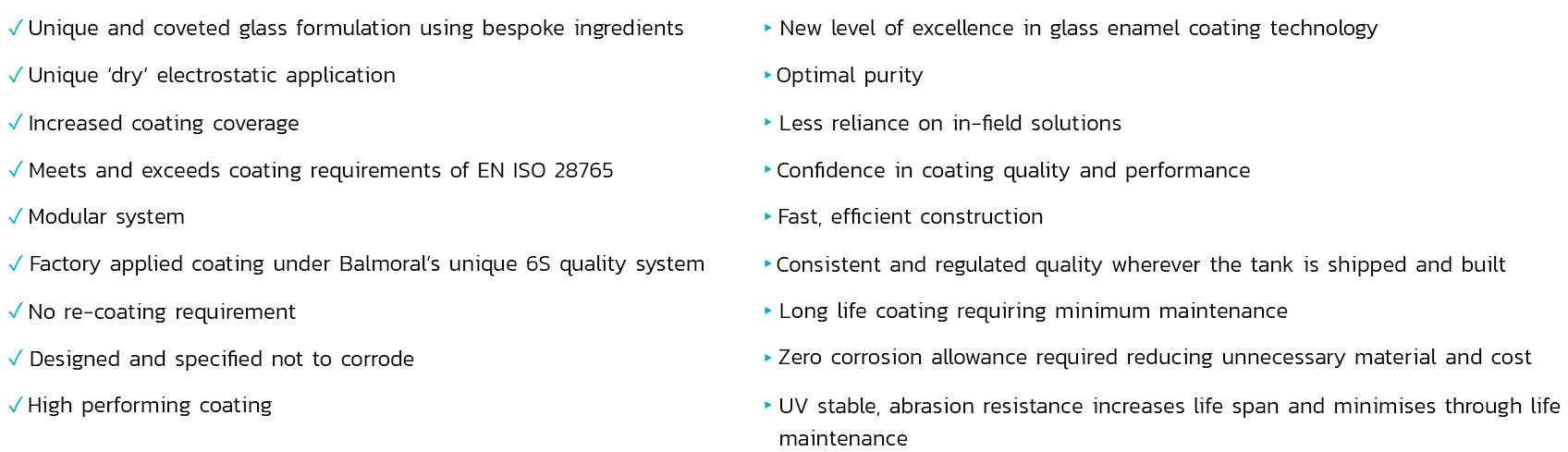

Balmoral’s efusion system, and its inherent performance properties, ensures the end user receives the best design life expectancy available. The company’s quality assurance standards and installation experience delivers a robust product that is more than capable of design life performance. GLASS FUSED TO STEEL TANKS    The term vitreous enamel comes from the word vitrification describing the transition of a substance into a glass. At typical vitreous enamel firing temperatures, usually in the range of 830-850°C, the coating reaches full mobility and viscosity.

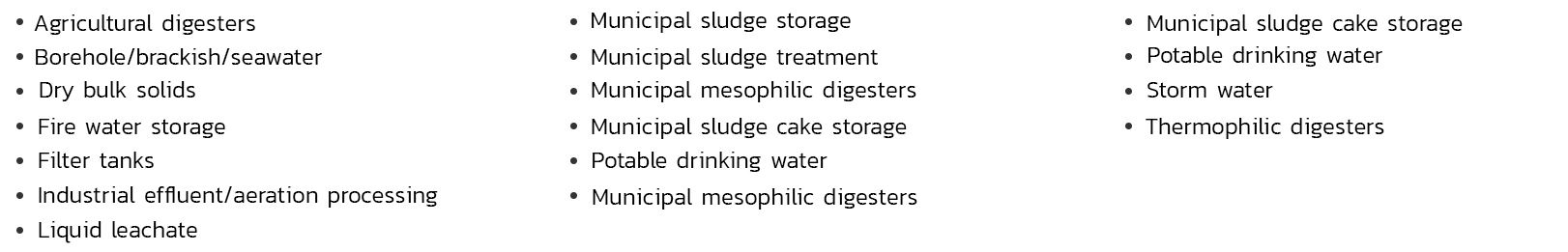

Balmoral's manufacturing process was designed to provide clients with a high performing, economical coating designed specifically for the containment of potable water and uncovered municipal wastewater tanks. Balmoral GFS Premium The Premiun option was developed to deliver heightened performance and long-term value to asset owners and users around the world in more demanding applications.

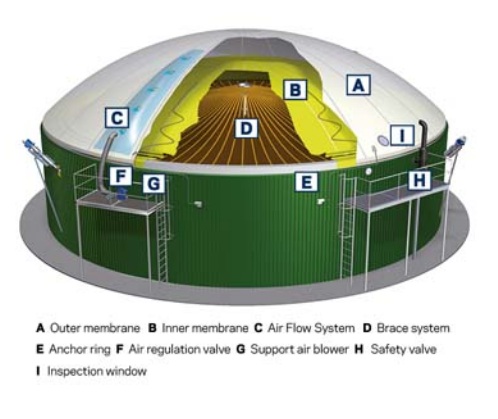

Appication  BIOGAS Balmoral มีประสบการณ์เกี่ยวกับถังเหล็กเคลือบแก้ว (Glass fused-to-steel) ที่ใช้ในการผลิตก๊าซชีวภาพมากว่า 40 ปี และเป็นที่รู้จัก และยอมรับไปทั่วโลก ในช่วงทศวรรษที่ผ่านมาถังเหล็กเคลือบแก้วเหมาะสำหรับการหมักวัตถุดิบ เพื่อการผลิตก๊าซชีวภาพที่หลากหลาย ในภาคอุตสาหกรรมหมักก๊าซชีวภาพ เพื่อผลิตพลังงานทดแทนได้เพิ่มขึ้นอย่างต่อเนื่องและรวดเร็ว ของเสียจากครัวเรือน ร้านอาหาร วัตถุดิบจากฟาร์ม มูลสัตว์จากปศุสัตว์ นำมาผลิตก๊าซชีวภาพ ซึ่งเป็นพลังงานสะอาด และในท้ายที่สุดวัตถุดิบที่ใช้ในการหมักจะเป็นปุ๋ย ซึ่งก่อให้เกิดมูลค่าทางเศรษฐกิจที่สำคัญอีกทางหนึ่ง แผ่นเหล็กเคลือบแก้ว (GFtS) ของ Balmoral มิได้ใช้เฉพาะการเป็รแผ่นผนังของตัวถังเท่านั้น ยังสามารถใช้เป็นแผ่นพื้นและหลังคาสำหรับรองรับก๊าซชีวภาพที่เกิดจากการหมักและเหมาะอย่างยิ่งกับก๊าซที่มีการกัดกร่อนสูง เพราะหลังคา GFtS สามารถรองรับวัตถุดิบตั้งต้นที่หลากหลายได้เป็นอย่างดีและประการสำคัญหลังคา GFtS มีความแข็งแรงสำหรับติดตั้งใบกวนอีกด้วย นอกจากนี้ ยังสามารถใช้ถังเหล็กเคลือบแก้ว เพื่อใช้ในการหมักก๊าซชีวภาพกับหลังคาเมมเบรนแบบ 2 ชั้น (Double membrane dome roof)

|

|